No, there is no such thing as a predetermined or mandated expiration date on fall protection harnesses. Neither OSHA or ANSI have current codes or standards that set a specific time period for taking a harness out of service. Even most manufacturers will not suggest how long a harness will last.

In fact, the only person who can truly determine when a harness is due for removal is you or your competent, trained inspector. But, the most important conversation to have is what actually determines a harnesses expiration rather than who determines when it is time for a replacement.

________________________________

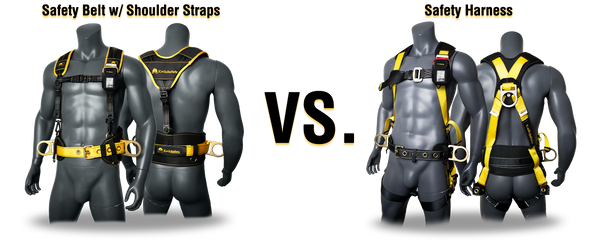

History of Safety Harnesses

Before OSHA requirements, workers used body belts that could cause significant injury during falls. Safety harnesses were previously body belts that exerted force on the abdomen, causing injuries, and these early designs often led to severe harm when falls occurred. As workplace safety standards evolved, OSHA requires safety harnesses to ensure safety in workplaces at heights, helping establish a new era of fall protection. Safety harnesses allow users to attach themselves to a stationary object to prevent falls, with restraints that prevent the wearer from falling from a height. The harness allows users to attach themselves to a stationary object, ensuring they do not hit the ground. The risk of serious injury due to falling was reduced when safety harnesses were implemented by OSHA, and OSHA requirements for safety harnesses have helped reduce casualties from falls in the workplace.

_________________

Introduction to Fall Protection

Fall protection is a cornerstone of workplace safety, especially in industries like construction, rock climbing, and rescue operations where working at heights is routine. Full body harnesses are essential components of fall protection systems, designed to distribute the force of a fall across the body and prevent serious injury or death. Falling from high areas is one of the most common causes of injuries in the workplace. So, whether you’re scaling a structure, performing a rescue, or working on a construction site, the proper use of a body harness can mean the difference between life and death.

Employers are responsible for ensuring that all employees receive comprehensive training on the correct use, inspection, and maintenance of safety harnesses. This training should cover how to properly don a full body harness, how to check for signs of wear or damage, and the importance of regular inspections. OSHA regulations require that any harness or fall protection equipment that does not pass inspection must be immediately removed from service, tagged as unusable, and destroyed to prevent accidental use.

Routine inspection is not just a recommendation—it’s a necessity. Harnesses that have been involved in a fall arrest event must be taken out of service without exception. Even if a harness appears undamaged, the forces involved in a fall can compromise its integrity. Regular, documented inspections help ensure that every piece of equipment in your fall protection system is ready to perform when needed, keeping workers safe and compliant with safety standards.

_________________

Full-Body Safety Harnesses

A full-body harness is designed to provide comfort and confidence for users, with design elements that enhance freedom of movement and ease of use. Certain full-body harnesses are specifically manufactured for different industries and applications, ensuring workers have the right equipment for their tasks. To maximize safety and usability, the full-body harness is adjustable in size to ensure a good fit and is made from durable materials like polyester combined with aluminum or steel components. Features such as lumbar support and positioning rings are also integrated into the design of full-body harnesses, giving users both safety and functionality while working at height.

These modern innovations not only meet OSHA standards but also help workers stay productive, comfortable, and secure while performing tasks at height.

_________________

The Problem With a Mandated Expiration Date

You might think that having a mandated expiration date for a fall protection harness would be a good thing. However, it could have some adverse effects.

For example, it could lull the wearer or safety professional into a false sense of security:

“My harness is only a year old, so I’m confident I’m adequately protected. This harness still has four year of use left in it.”

See the problem with that statement?

It is possible to become complacent, taking for granted that the harness will perform properly if and when needed. The wearer might even skip inspecting for defects each time the harness is used, which is extremely unsafe as this is the key to knowing if it is time to get a new harness or not.

_________________

What Affects a Fall Protection Harness’s Lifespan?

As with any PPE (personal protective equipment), a full body fall protection harness must be cared for and used properly.

Some of the things that can affect the durability of a safety harness are:

-

Snagging on objects that might cause tears to the harness’s fabric or stitching. This can cause a weak spot that could fail during a fall arrest.

-

Saturation of paints and other chemicals can weaken the synthetic materials used in the webbing construction. Remove chemicals as soon as possible, using the manufacturer’s guidelines to avoid further deterioration of the harness.

-

Excessive exposure to UV rays or sunlight may cause deterioration or weakening of synthetic fibers. When the harness is not in use, store it away from sunlight.

-

Exposure to caustics and acids may deteriorate the metal components, such as the D-ring and buckles. Clean these items as soon as possible using approved methods.

-

Improper storage methods can damage the harness. The harness should be stored in a hanging position so that the webbing can “relax.” Hang the harness by the D-ring, not the webbing.

***If your harness has already been subjected to a fall arrest, it must be taken out of service immediately. Do not use the harness after an impact event. It must be labeled as unusable, removed from service and destroyed.***

_________________

Determine Usability Through Routine Inspection

Checking the safety harness carefully for damage is the only reliable way to determine its condition. This includes a pre-use check by the wearer before donning the equipment, and the periodic inspection by a qualified and competent inspector.

A competent inspector will be trained in proper inspection procedures and should document each harness’s inspection with a log sheet. While the pre-use inspection is necessary, the closer look an inspector gives the equipment ensures the harness is inspected properly.

ANSI recommends that formal inspections should be done at intervals of no more than six months.

***We advise that a harness that has not been formally inspected within that six month period be taken out of service and tagged unusable until a formal inspection is completed, including documentation.***

_________________

A Five Step Procedure for Harness Inspection

Below are the five steps you should follow in doing a formal inspection.

1. Inspect all webbing and stitching

- You’re checking for cuts, fraying, pulled or broken threads, abrasions, excessive wear, altered or missing straps, burns, UV damage, and heat and chemical exposures. Starting at one end of a webbing length, grasp the webbing with hands eight inches apart and flex the fabric. This can expose any defects not seen with the webbing in a straight alignment.

2. Inspect all metal or plastic components of the harness

- All harness buckles should work freely, engaging and disengaging fully and smoothly. Depending on the model harness you use, make sure each type of buckle, including a quick connect buckle, is functioning properly.

- Look for deformation, cracks, corrosion, deep pitting or burrs, sharp edges, nicks or cuts, exposure to excessive heat or chemicals, and any other damage. Missing, loose or improperly working parts should be noted. This should include both metal and plastic components.

- The D-ring should not be cracked, deformed, or otherwise damaged.

3. Inspect all load indicators

- Load indicators are sections of the harness webbing that are folded over and stitched securely. Ripped stitching, even if only partially separated, is an indicator that the harness has been subjected to a fall and is no longer providing adequate protection. Remove the harness from service immediately. Mark it as unusable until such time as it can be destroyed.

4. Inspect all labels

- To fully pass inspection, labels must be present and readable. Make sure the unique identifier for the harness is legible so that it can be marked properly on the log sheet.

5. Complete All Inspection Documentation

-

A formal inspection is not done until the paper work is filled out. Create a log sheet if necessary, covering all the check points for the harness you use.

- Many suppliers, like MSA Safety, can furnish you with a complete, fully itemized inspection log for each model they sell. Your log should have a place to enter condition codes, overall assessment scores, and room for the inspector to make comments.

- Keep in mind that assessment doesn’t work on a sliding scale. The component, no matter what it is, gets a Pass OR Fail rating. There is no in-between.

At KwikSafety we always say that if there is any doubt, change it out!

_________________

Storage and Handling

Proper storage and handling of full body harnesses are vital to maintaining their effectiveness and extending their service life. Harnesses should always be stored in a cool, dry environment, away from direct sunlight, moisture, and sources of heat, as exposure to these elements can degrade the webbing and compromise the safety of the equipment. Avoid placing harnesses near dangerous equipment, chemicals, or sharp objects that could cause accidental damage.

When not in use, hang harnesses by their D-rings or store them in protective bags to prevent the straps from becoming tangled, creased, or crushed. This helps maintain the snug fit and structural integrity required for optimal protection. Before each use, inspect all components—including D-rings, straps, and buckles—to ensure they are secure, free from corrosion, and functioning properly.

Regular cleaning is also essential. Follow the manufacturer’s guidelines for cleaning your harness, using mild soap and water to remove dirt and contaminants, and allow the harness to air dry completely before storage. Never use harsh chemicals or machine washing, as these can weaken the webbing and stitching.

Employers should implement a system for tracking inspections and maintenance, keeping accurate records to demonstrate compliance with OSHA regulations. By prioritizing proper storage, handling, and documentation, you help ensure that your fall protection equipment remains reliable, compliant, and ready to protect workers from the risks of falls on the job.

***In order to meet OSHA requirements, any type of equipment that does not pass inspection must be withdrawn from service immediately and tagged or marked as unusable or destroyed.***

_________________

Regular Inspections

You should be inspecting your harnesses regularly before every use, and it should be thoroughly inspected by a competent person periodically to ensure it is still in safe condition for use.

It’s common for safety harnesses to experience normal wear and tear; just be sure that it is in safe condition before you use it.

When determining whether or not to replace your safety harness, consider the following questions:

- Is there a chance that your safety equipment is compromised? If so, replace it.

- Is there a chance that your safety harness has been involved in a fall? If so, replace it.

Everyone in your organization who uses fall protection equipment must know that a safety harness needs to be replaced if it fails an inspection for any reason.

***In order to meet OSHA requirements, any type of equipment that does not pass inspection must be withdrawn from service immediately and tagged or marked as unusable or destroyed.***

_________________

Making the Final Decision

Ultimately, the decision to retire a safety harness is up to you, once you’ve clearly evaluated the effectiveness of the harness. However, when you invest in high-quality fall protection equipment, such as the line we have at KwikSafety, you may get many more years – and jobs – out of the equipment.

At KwikSafety, we can’t speak for any other manufacturers, but we do not put an expiration date on any of our products.

As long as your harness passes your user inspections, both daily for pre-use and annually by your competent person, you are okay to use these products all the time!

OSHA 1926 Subpart M • ANSI Z359 • Fit & Inspection • Training

Important U.S. Safety Harness Regulations You Need to Know

When working at height, a safety harness isn't just equipment — it’s your last line of defense. But not every harness offers the same level of protection. To stay safe and compliant, workers and employers must follow strict U.S. regulations that govern how harnesses are used, tested, and maintained.

This guide explains:

✅ OSHA Fall Protection Requirements – What the law says about harness use and when it's required.

✅ ANSI Z359 Standards – How ANSI goes beyond OSHA with rigorous best practices.

✅ Fit, Inspection & Training – How to ensure your harness is worn correctly and kept in safe condition.

Let’s break it down.

Read more

_____

OSHA Fall Protection Requirements (29 CFR 1926 Subpart M)

The Occupational Safety and Health Administration (OSHA) sets the legal minimum safety standards for working at height in the United States.

Key OSHA Guidelines for Safety Harness Use

🔹 Fall protection is required at:

• 6 ft in construction

• 4 ft in general industry

• 10 ft on scaffolds

🔹 A full-body harness is required as part of a Personal Fall Arrest System (PFAS).

🔹 PFAS must include:

• A harness

• An anchor point rated at 5,000 lbs per worker

• A connecting device (lanyard or SRL)

🔹 Maximum arresting force allowed on the body: 1,800 lbs

🔹 Free fall distance must not exceed 6 ft

🔹 Harnesses must be inspected before each use

📌 OSHA’s rules are mandatory and apply to all U.S. job sites.

_____

ANSI Z359: The Industry's Best Practice Standard

While OSHA sets the law, the American National Standards Institute (ANSI) outlines voluntary best practices that manufacturers and safety professionals follow to go beyond minimum compliance.

OSHA vs. ANSI: What’s the Difference?

| Feature |

OSHA Requirement |

ANSI Z359 Best Practice |

| Fall Protection Height |

6 ft (construction) |

Same as OSHA |

| Arresting Force Limit |

1,800 lbs |

1,800 lbs |

| Harness Certification |

Not required |

Required to meet Z359.11 |

| Labeling |

Basic manufacturer info |

Must include model, size, ANSI code, and date |

| Inspection Frequency |

Before each use |

Before use + documented annual inspection |

| Rescue Planning |

Not mandated |

Strongly recommended |

| Retirement Criteria |

After fall/damage |

After fall, expiration, or as defined by manufacturer |

| Training Requirement |

Required (29 CFR 1926.503) |

Reinforced with best-practice content |

🔍 KEY TAKEAWAY: OSHA tells you what you must do — ANSI shows you how to do it better.

_____

Proper Fit & Usage: A Critical Factor in Fall Protection

Even a fully certified harness won’t work if it’s worn incorrectly.

Harness Fit & Usage Best Practices

✅ Use the back D-ring (between shoulder blades) for fall arrest

✅ Adjust leg and chest straps to ensure a snug, secure fit

✅ Ensure buckles and connectors are locked and tight

✅ Only attach to certified anchor points

❌ Never tie off to railings, pipes, or temporary structures

📌 Workers should be trained to inspect and adjust their harness properly before each use.

_____

Harness Inspection & Retirement Guidelines

Your harness should be treated like mission-critical equipment. Daily wear and environmental exposure can degrade its integrity over time.

What to Check During Inspection

✅ Webbing: No fraying, cuts, burns, or UV damage

✅ Stitching: Secure, intact, and consistent

✅ Hardware: No rust, cracks, or distortion

✅ Labels: Must remain legible for OSHA/ANSI compliance

❌ Immediately remove any harness that has been involved in a fall.

📆 Recommended inspection frequency:

_____

Training is Mandatory Under OSHA 1926.503

Workers must be trained in fall protection before using any harness system.

What Fall Protection Training Must Cover:

✅ How to wear and adjust a harness properly

✅ How to identify fall hazards

✅ When to inspect or retire equipment

✅ How to respond after a fall

📌 Training must be:

-

Provided at no cost to employees

-

Updated whenever new equipment or hazards are introduced

-

Documented and conducted by a qualified instructor

_____

Final Takeaways: Mastering Harness Safety Compliance

🔹 OSHA sets the baseline for legal compliance

🔹 ANSI Z359 outlines the best practices for high-risk environments

🔹 Proper fit, inspection, and training are non-negotiable

🔹 Harnesses must be worn correctly, inspected often, and retired responsibly

🔹 Employers are responsible for providing training, compliant gear, and rescue planning

🎯 PRO TIP: Always check for ANSI Z359.11-2021 certification when purchasing a new safety harness — and don’t forget to inspect it before every use.

↑ Back to top

Webbing • Buckles • D-Rings • Padding • Inspection

The Anatomy of a Safety Harness

In the world of personal protective equipment (PPE), the safety harness is one of the most critical pieces of gear for anyone working at heights. Whether you’re on a construction site, climbing a tower, or performing maintenance on tall structures, a safety harness is your lifeline—literally. However, the effectiveness of a safety harness is directly tied to the integrity and functionality of its components.

Understanding the anatomy of your safety harness and how each part contributes to your overall safety is crucial for preventing accidents and ensuring your harness performs as intended in a fall situation.

Read more

Webbing: Materials and Strength

The webbing is the backbone of your safety harness. It’s the network of straps that wrap around your body, securing you in place. Typically made from durable materials like polyester or nylon, the webbing is designed to withstand significant forces during a fall. Polyester is known for its resistance to UV rays and chemical degradation, making it ideal for outdoor use, while nylon offers excellent strength and elasticity.

The webbing's strength is measured in terms of tensile strength, which is the maximum load it can bear without breaking. For safety harnesses, this is typically around 5,000 pounds, ensuring it can support the wearer during a fall arrest. The webbing must be free from cuts, frays, or abrasions to maintain its integrity, so regular inspection is vital.

Buckles: Types and Their Uses

Buckles are the fastening mechanisms that secure the harness to your body. They allow you to adjust the fit of the harness and ensure it stays in place during use. There are several types of buckles used in safety harnesses, including:

-

Tongue Buckles: Similar to a traditional belt buckle, these offer a secure fit and are easy to adjust, making them a popular choice for many harnesses.

-

Quick-Connect Buckles: These snap together and release quickly, providing convenience and ease of use.

Each type of buckle has its advantages, and the choice often comes down to personal preference or specific job requirements. Proper adjustment of the buckles is crucial to ensure the harness fits snugly and won’t slip or come loose during a fall.

D-Rings: Placement and Importance

D-Rings are the attachment points on the harness where your lifeline or lanyard connects. The primary D-ring is typically located on the back, between the shoulder blades, as this position provides the most effective fall arrest and minimizes the risk of injury. Some harnesses also feature additional D-rings on the sides or front, which are used for positioning or climbing tasks where more mobility is needed. Ensuring the D-ring is correctly positioned and secured is an essential part of harness safety.

Padding: Comfort vs. Protection

While the primary purpose of a safety harness is to protect you during a fall, comfort is also a significant consideration. Padding plays a crucial role in this. Located around the shoulders, waist, and legs, padding helps distribute the forces experienced during a fall, reducing pressure points and making the harness more comfortable to wear for extended periods.

However, it’s essential to strike a balance between comfort and protection. Overly padded harnesses may feel more comfortable but can be bulkier and more cumbersome, potentially hindering movement. Conversely, minimal padding may lead to discomfort, especially during prolonged use, but allows for greater freedom of movement. Choosing the right level of padding depends on the nature of the work and how long you’ll be wearing the harness.

______________________

Understanding the anatomy of a safety harness is not just about knowing the names of the components—it's about recognizing how each part contributes to your safety and how to properly maintain your gear. Before each use, take the time to inspect your harness thoroughly:

- Check the webbing for any signs of wear or damage.

- Ensure that all buckles are functioning correctly and securely fastened.

- Verify that the D-ring is properly positioned and in good condition.

- Confirm that the padding is intact and provides adequate comfort without compromising protection.

By taking these steps, you not only ensure the longevity of your safety harness but also, more importantly, protect yourself from the hazards of working at heights. Remember, your harness is only as reliable as the care you put into it.

↑ Back to top

Tongue Buckle • Quick-Connect • Pass-Through • Pros/Cons • Best Uses

Harness Buckle Types Explained: Tongue Buckle vs. Quick-Connect vs. Pass-Through

When it comes to fall protection, your harness isn’t just about D-rings and padding—the buckle style plays a big role in your comfort, fit, and job performance. Whether you're a tower tech, ironworker, or utility crew member, choosing the right buckle system matters.

Below, we break down the three most common harness buckle types—Tongue Buckle, Quick-Connect, and Pass-Through—and help you decide which is right for the work you do.

Read more

_____

Tongue Buckles

Style: Belt-like prong and grommet system

Commonly Found On: Leg straps

✅ Pros:

• Extremely secure and unlikely to loosen on the job

• Simple design that’s easy to inspect for damage

• Great for hot, dirty, or rugged conditions

⚠️ Cons:

• Takes longer to put on and adjust

• Can be stiff when new or wet

• Prone to wear around grommets over time

🔧 Best For:

• Construction

• Steel erection

• Heavy-duty jobs with a lot of debris and movement

_____

Quick-Connect Buckles

Style: Snap-together metal clips (like a seatbelt)

Commonly Found On: Chest and leg straps

✅ Pros:

• Fastest and easiest buckle to use

• Ideal for shared harnesses or frequent donning/doffing

• Clean, modern, and minimal bulk

⚠️ Cons:

• More expensive than other styles

• Can clog with dirt or mud if not maintained

• Latch mechanisms must be checked frequently

🔧 Best For:

• Tower work

• Utility/linework

• Maintenance techs with frequent gear changes

_____

Pass-Through Buckles

Style: Metal loop system where one strap is threaded through another

Commonly Found On: Chest, leg, or shoulder straps

✅ Pros:

• Lightweight and affordable

• Once adjusted, stays in place well

• No moving parts = less to fail

⚠️ Cons:

• Slower to put on and adjust

• May loosen slightly with heavy movement

• Less intuitive for first-time users

🔧 Best For:

• General construction

• Roofing

• Entry-level or part-time workers

_____

What’s Right for You?

No buckle type is better than the others—it all comes down to your work environment, daily needs, and personal preference.

- Need speed and ease? Go Quick-Connect.

- Want rugged security? Choose Tongue Buckles.

- Prefer lightweight and budget-friendly? Pass-Through works great.

👉 Click here to browse our full collection of ANSI-tested, OSHA-compliant safety harnesses with all three buckle styles available!

↑ Back to top

Leave a comment